Utility of the Month: Lamborghini Makes use of 3D printing for the SC63 Hypercar on the 24 Hours of Le Mans 2024

Using 3D printing in motor racing has change into more and more frequent. The power to quickly produce, customise and choose probably the most acceptable supplies for every software has led many automakers to undertake this know-how. In Formulation 1, for instance, the collaboration between Visa Money App RB and ROBOZE illustrates this development, as do initiatives by Ferrari and McLaren Racing, amongst others.

A latest software of 3D printing on the racetrack is the event of elements for Lamborghini’s new SC63 hypercar. Notably, throughout the 24 Hours of Le Mans, Lamborghini urgently known as on native firm EProjets Lab to 3D print elements in any other case unavailable, however important for the race.

Lamborghini hypercars on the 24 Hours of Le Mans 2024 (picture credit: Lamborghini)

Lamborghini and Iron Lynx Be part of Forces to Take Endurance Racing to the Subsequent Stage

Lamborghini’s unimaginable SC63 hypercar was revealed on the Goodwood Pageant of Velocity 2023, an annual motorsport occasion held on the Goodwood circuit in England. The automobile subsequently took half within the 2024 World Endurance Championship (FIA WEC) and the IMSA WeatherTech SportsCar Championship, marking a big milestone for Lamborghini. The SC63 is a hybrid prototype powered by a 3.8-liter twin-turbo V8 engine, representing probably the most superior racing automobile ever constructed by the Italian automaker.

For the 2024 races, Lamborghini has established a strategic partnership with Iron Lynx to optimize the automobile’s efficiency and entice world-class drivers from Formulation 1 and endurance racing, reminiscent of Mirko Bortolotti, Andrea Caldarelli, Daniil Kvyat and Romain Grosjean.

3D Printing for the SC63 on the 24 Hours of Le Mans

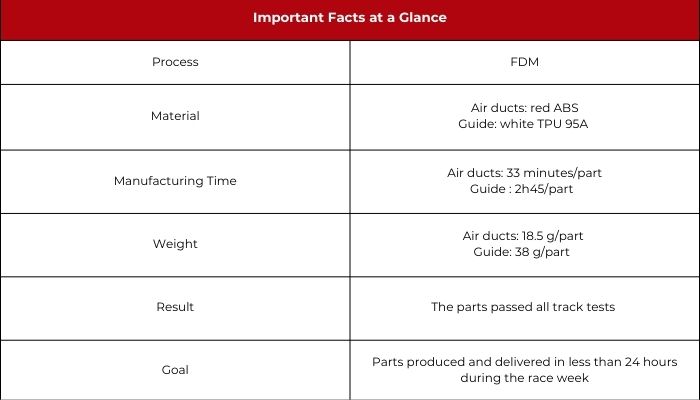

Throughout the fourth spherical of the FIA WEC championship, the 24 Heures du Mans, Lamborghini and Iron Lynx commissioned EProjets Lab to urgently produce a sequence of elements utilizing 3D printing. These elements included two air ducts for the cockpit air flow system, to make sure optimum thermal administration for the drivers, and two guides for the automobile’s pneumatic lifting system. These guides had been important to facilitate pit stops, making certain appropriate and dependable operation of the insertion and elimination system.

The 3D-printed ABS air ducts for the cockpit air flow system: it brings recent air into the automobile for driver consolation (picture credit: EProjets Lab)

The air ducts had been manufactured utilizing the FDM course of from crimson ABS, which ensured the half’s power and lightness. For the guides, however, the problem was to fabricate them in a brief house of time and utilizing sturdy, sturdy supplies, as these elements had already skilled resistance issues previously. Certainly, these elements are ejected as soon as the pit cease is over, and break simply as they fall onto the asphalt. It was subsequently vital to decide on a cloth that was versatile and powerful sufficient to not break after repeated falls.

The 3D printing materials TPU 95A proved to be the optimum selection, as a result of its flexibility and affect resistance, making certain dependable, long-lasting efficiency even underneath excessive circumstances. The FDM course of was once more chosen for this software.

3D-printed half in white TPU95A to optimize efficiency and precision throughout pit stops (picture credit: Lamborghini, Iron Lynx)

EProjets Lab delivered the 3D printed elements in lower than 24 hours, as confirmed by the 3D printing service. This fast turnaround was made doable by the pliability and pace of additive manufacturing. “We acquired the elements in a short time, at a aggressive value and with distinctive high quality. We’re very impressed,” says John McGill, Engineering Coordinator at Iron Lynx Lamborghini.

3D printing was thus capable of meet Lamborghini’s and Iron Lynx’s particular necessities by way of manufacturing time, precision and customization. After the 2024 Le Mans 24 Hours, the elements 3D printed by EProjets Lab underwent additional testing, confirming their sturdiness. Lamborghini SC63s additionally used these elements on the IMSA 6 Hours of Watkins Glen, acting on the Watkins Glen Worldwide Circuit all through the race. For extra info, go to the web site HERE.

What do you consider Lamborghini’s use of 3D printing within the 24 Hours of Le Mans? Tell us in a remark under or on our LinkedIn, Fb, and Twitter pages! Don’t overlook to join our free weekly e-newsletter right here for the newest 3D printing information straight to your inbox! You can even discover all our movies on our YouTube channel.

*Cowl Photograph Credit: Lamborghini