Meltio increases the usability and ease of LMD3D printing using new Horizon software.

The 3D Printing Industry Awards, 2022 Voting for the shortlists is now possible. Vote now to determine who will win the 2022 3DPI Awards. Cast your vote today to let us know your opinion.

Meltio, a metal 3D printer manufacturer, has added two products to its portfolio at Formnext: the Meltio HORIZON software and a Laser Calibration system.

While the former features pre-programmed print and material profiles, designed to help users get their Meltio systems up and running, the latter can be used to easily calibrate these units’ multi-laser deposition heads. Between them, the firm says its latest additions make its machines easier to use, while “eliminating the barriers” preventing metal 3D printing from addressing industrial applications.

“With the launch of our new software, we facilitate and shorten the learning time for you to democratize metal 3D printing so that your software is accessible and easy to use for many different profiles within a company,” said Meltio CEO Ángel Llavero. “The Laser Calibration System will give industrial companies a new tool to be able to work with guaranteed reliability in the creation of their metal parts.”

Laser Metal Deposition at Meltio

Meltio, a joint venture of Sicnova & Additec, was established three years ago. The company is focused on wire Laser Metal Deposition (LMD). A form of Directed Energy Deposition (DED), the firm’s process sees multiple fiber-coupled diode lasers used to melt metals fed out of a central nozzle. Weld beads form when the lasers collide with alloys. These can be deposited onto substrates below layer-by–layer to make fully-dense parts.

The company sells its technology through the Meltio M450 (and Meltio engine) toolheads. These can be attached seamlessly to CNC machines and robotic arms as well as gantry and gantry system gantry systems. These two functions use a multi-laser head that contains the 1.2kW lasers required to transform powder or wire feedstocks (including nickel, stainless steel, titanium and copper) into complex parts.

In addition to its LMD 3D printing engine and proprietary 3D printer, the company also started selling wire-based Meltio Materials earlier in the year. The company’s traditional offering was open-material. This move marked a major shift in direction. The range was initially marketed to adopters as a way to increase print success rates and provide a simpler user experience.

Meltio’s Horizon slicer launch

With its Horizon software, Meltio has introduced a proprietary toolpath generator that can be customized to the needs of adopters’ individual applications. To date, users of the firm’s plug-and-play Meltio M450 3D printer have been forced to rely on third-party Fused Filament Fabrication (FFF) slicers to prepare toolpaths for prints, but now they can access presets that streamline the whole process.

Meltio Horizon allows you to access material-specific laser power, dualwire and hotwire settings. Utilizing this functionality, users are able to create specialized printing profiles, which allow for direct control over the laser and hot wire on a ‘per slicing feature’ basis, rather than being set for the full part.

The program also comes made to measure for Meltio’s wire-laser metal 3D printing process, in a way that could provide adopters with future cost savings. Meltio Horizon allows users to set up their gas source and calculate the cost. Flow rates can be defined for each material. The cost calculator also allows users to price-model each project.

The M450 system is the only compatibility at launch. Meltio, however, is working to develop its open-source software ecosystem partnerships so it can create 5-Axis Gcodes CNC and Robot Integration Meltio Machines.

Convenient laser calibration

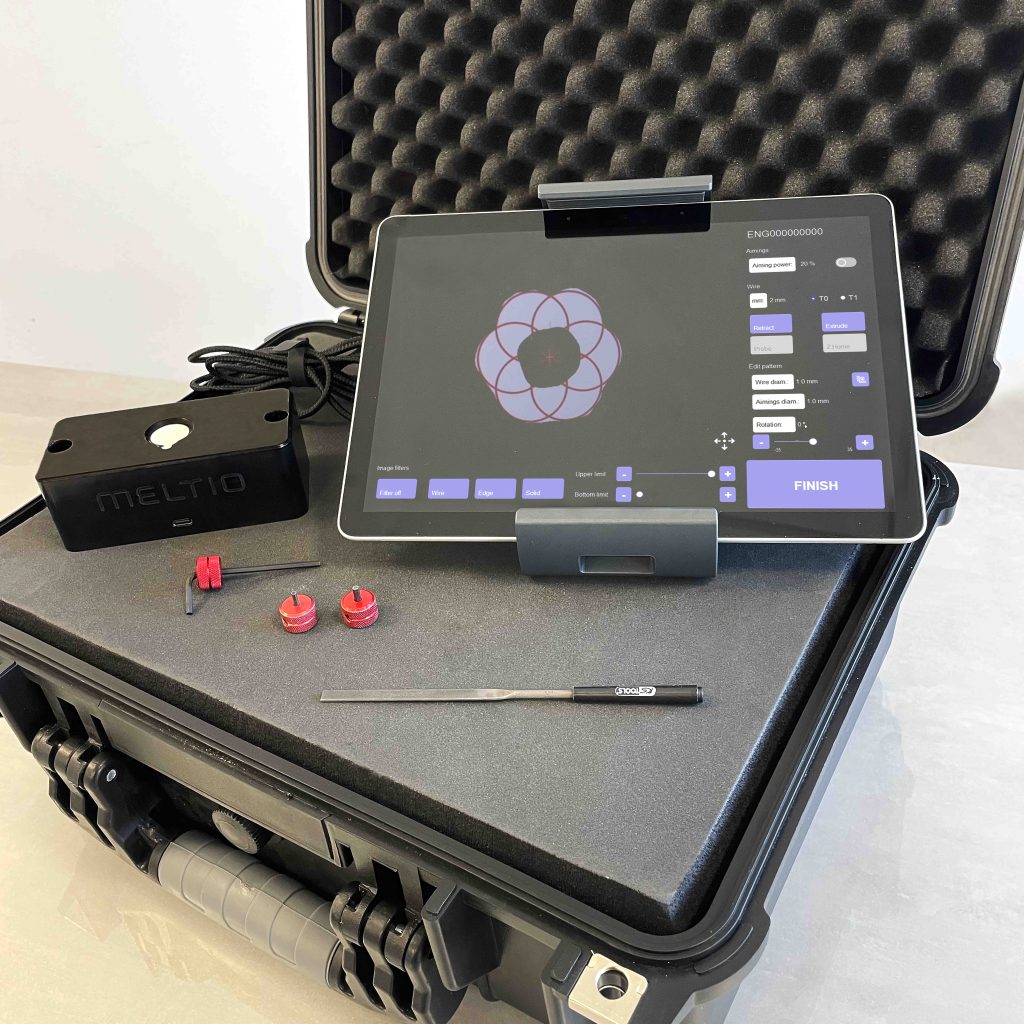

Essentially an add-on for calibrating Meltio printheads, the firm’s new Laser Calibration Tool is designed to make the 3D printing process more reliable, and easier to manage. The system includes a laser alignment camera that can be placed under machines’ deposition heads, in a way that provides users with a clear view of their lasers’ focus points.

Shipped with a portable controller and software designed to filter resulting images, this kit is said to guide users’ efforts to focus each laser on the most optimal point. Meltio claims that the new package is easier than manual calibration and can be used to align lasers correctly.

The whole alignment process is fast as well, with the company boasting that it’s twice as quick to carry out as manual alternatives, and once complete, it’s said to enhance Meltio 3D printing repeatability and traceability. Unlike with its Horizon software, the calibration tool is also compatible with Meltio’s M450 printer and CNC and Robot Integration Engines, making it available to the firm’s entire user base.

See our complete list Formnext news round-up for the latest from 3D printing’s leading trade show.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry Newsletter Follow us on Twitter You can also like our page Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, and video shorts.

Are you interested in a job within the additive manufacturing sector? Visit 3D Printing Jobs Here are some examples of the roles available in this industry.

The Meltio Laser Calibration System can be seen in the featured image. Photo by Meltio.