NematX launches new NEX 01 Liquid Crystal Polymer 3D printer at Formnext

The 3D Printing Business Awards 2022 shortlists at the moment are obtainable for voting. Who will win the 2022 3DPI Awards? Have your say by casting your vote now.

Swiss extrusion 3D printing start-up NematX has introduced the launch of the NEX 01 3D printer on the Formnext commerce present.

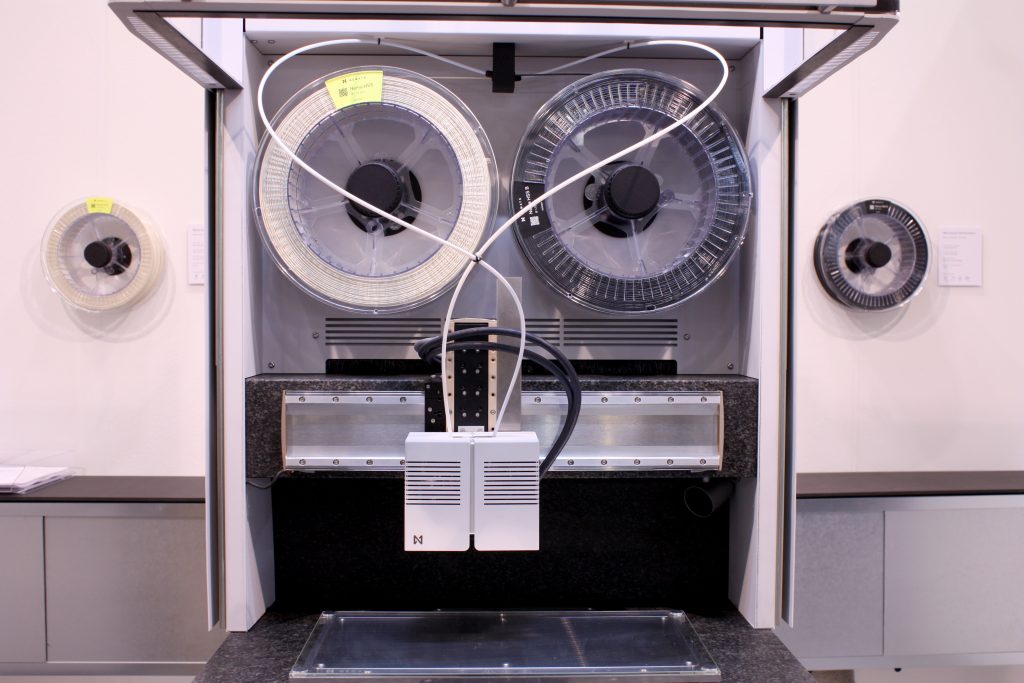

Designed to allow excessive throughput manufacturing with most course of management, the NEX 01 is powered by a movement management system and slicing algorithm that lend it micron-resolution 3D printing capabilities. These, in tandem with the machine’s Liquid Crystal Polymer (LCP) compatibility, are mentioned to make it nicely suited to assembly industrial functions in essentially the most demanding of manufacturing environments.

LCP 3D printing at NematX

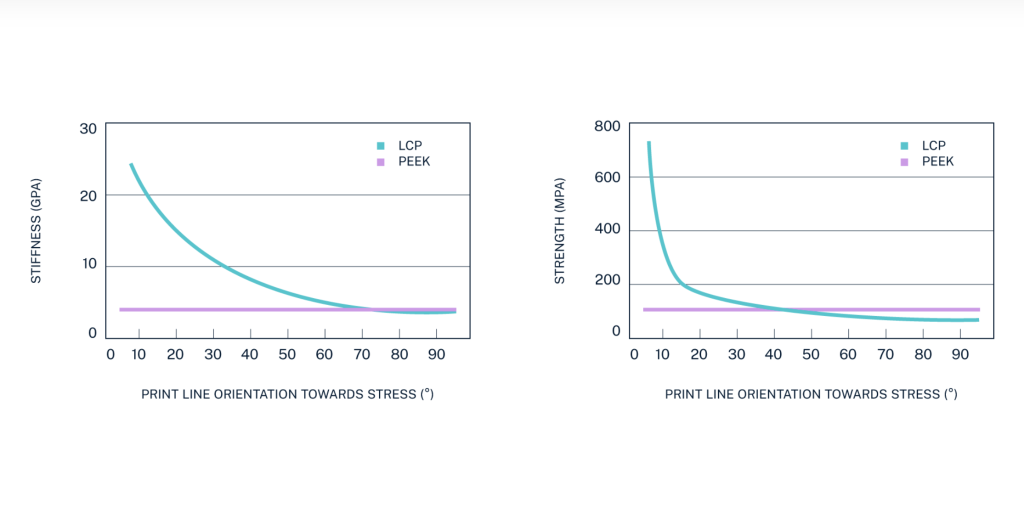

In comparison with supplies like PEEKs or PEIs, LCPs are made up of shorter, stiffer molecules which are organized in a manner that gives them with enticing power traits. Round these polymers, NematX has developed a Nematic 3D Printing know-how. Utilizing Fused Filament Fabrication (FFF), this course of aligns LCPs alongside the print course, to ship mechanically-enhanced elements.

Leveraging its know-how, NematX boasts of with the ability to create prints with a Younger’s moduli of as much as 25 GPa and supreme tensile power of 650 MPa. The ETH Zurich spin-off’s method has additionally seen it acknowledged as an trade innovator and helped it set up a consumer base. NematX gained the Formnext Begin-up Problem in 2020, and it has now begun advertising and marketing its personal vary of LCP filaments.

Mentioned to be ten occasions stronger than PEEK, these chemically and biologically inert supplies characteristic low-flammability, excessive radiation resistance, and permit for the manufacturing of elements inside an accuracy of 25 µm. NematX says it additionally produces its LCPs to the “highest high quality requirements” utilizing a complicated in-line monitoring system to constantly management filament diameter and ovality throughout manufacturing.

The corporate doesn’t but record its full materials providing by way of its web site, however these can attain out and request a quote from NematX instantly.

Introducing the NEX 01 3D printer

With the NEX 01, NematX has launched a business 3D printer to enrich its software program and materials portfolio. In apply, the system works by controlling LCPs’ molecular alignment throughout extrusion to allow the creation of elements with improved thermal, organic, mechanical and chemical properties. In comparison with conventional 3D printing supplies, LCPs may also be deposited with a lot greater precision and pace, therefore the NEX 01 affords vital potential throughput advantages.

To allow customers to completely make the most of these LCP 3D printing benefits, NematX has fitted the NEX 01 with a movement management system that permits them to intently handle extrusion quantity. The machine additionally comes with a fast construct plate change setup that facilitates quantity manufacturing, along with a fully-integrated course of monitoring system, which permits adopters to make sure half high quality.

As soon as launched, the agency anticipates that the NEX 01’s high-grade parts and LCP 3D printing capabilities will unlock the “serial manufacturing of complicated technical merchandise.” The machine is now commercially obtainable, with the primary items scheduled for supply in Q2 2023, and it’s additionally set to be deployed in assist of NematX’s 3D printing R&D and customized half manufacturing companies.

“With our choice to supply tailor-made {hardware} and software program options for our supplies, we didn’t take the trail of least resistance” explains NematX CEO Raphael Heeb. “However because of our holistic method, now we have the prospect to set new requirements in polymer 3D printing by combining half efficiency with excessive manufacturing precision.”

LCPs little question have industrial manufacturing potential, however they’re removed from the one high-performance polymers within the 3D printing house. With the launch of its Plus PRO 3D printers earlier this yr, Roboze additional expanded its high-temp PEEK manufacturing providing, which continues to seek out demanding aerospace and protection functions.

Taking a barely totally different method with its Steady Fiber Reinforcement Know-how, Markforged additionally gives customers with a manner of 3D printing high-strength polymers. Nonetheless, the method does so by way of a type of carbon fiber reinforcement, which is designed to yield prints which are robust, stiff and sturdy sufficient to switch aluminum elements.

Try our full Formnext information round-up for the newest from 3D printing’s main commerce present.

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Business publication or observe us on Twitter or liking our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? that includes dialogue, debriefs, video shorts and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a collection of roles within the trade.

Featured picture exhibits the NematX NEX01 at Formnext 2022. Photograph by way of NematX.