New 3D printer ink makes recyclable electrical circuits with out warmth or gentle

Scientists from the U.S. and Korea have developed an revolutionary new ink for 3D printing that may construct easy-to-recycle electrical circuits and different buildings with out the necessity for warmth, gentle, or poisonous chemical compounds. Their analysis was just lately revealed in Nature Communications, supported by the Nationwide Science Basis within the U.S. and the Nationwide Analysis Basis of Korea.

In most types of 3D printing, the uncooked materials requires a mixture of warmth, stress, and lightweight to turn out to be a inflexible construction. In FDM printing, the filament have to be melted after which cooled into its fashioned form. With resin 3D printing, ultraviolet gentle is utilized to the liquid materials to harden and remedy it.

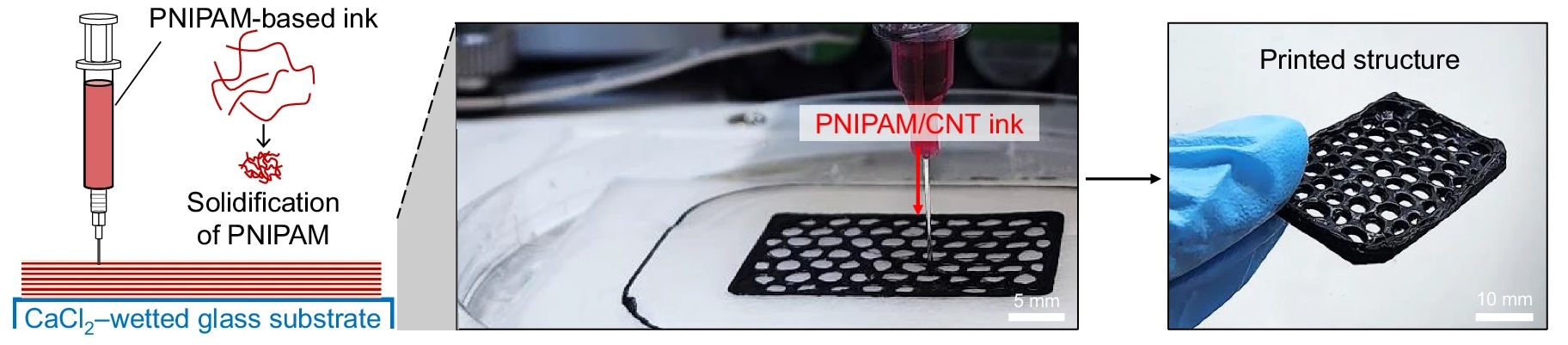

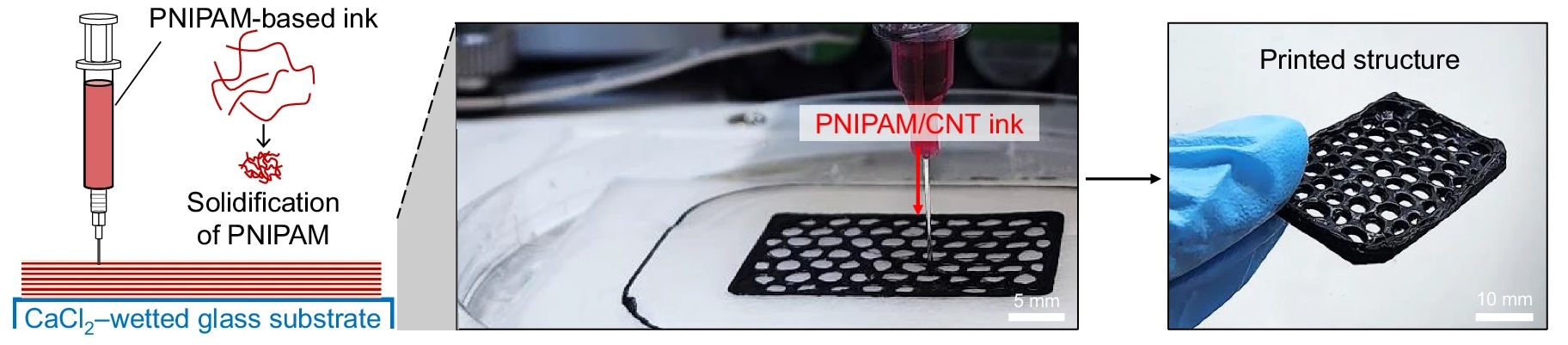

On this new strategy, the analysis workforce makes use of a polymer known as poly(N-isopropylacrylamide), or PNIPAM. PNIPAM is non-toxic and utilized by the pharmaceutical trade for drug supply programs. In 3D printing, all that’s wanted to solidify the PNIPAM is salt water at room temperature.

The researchers extruded the polymer utilizing a industrial healthcare-grade 3D printer to pump the fabric into mixtures of calcium chloride and water. It solidified instantly into neat, intricate buildings able to conducting electrical energy.

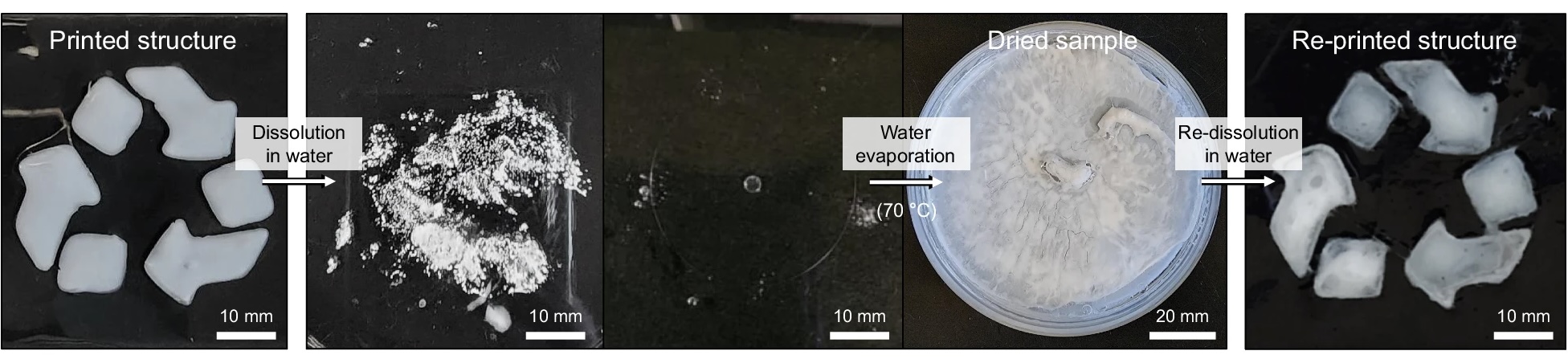

The workforce used the strategy to make an electrical circuit blended with carbon nanotubes, which then powered a small gentle bulb. Recycling the fabric was completed by dissolving the buildings in recent water after which evaporating the water in an oven at 158º F (70º C).

Senior writer Professor Jinhye Bae from the College of California, San Diego, identified that the strategy “is all performed beneath ambient circumstances, without having for extra steps, specialised tools, poisonous chemical compounds, warmth or stress.” Because the polymer is definitely reverted to its uncooked state, buildings made with PNIPAM could possibly be helpful for disposable electronics, robotic elements, and prototyping.

“This presents a easy and environmentally pleasant strategy to recycle polymer supplies,” Bae added. Given the growing must take care of e-waste, the power to recycle electrical circuits from gadgets so simply could possibly be an actual boon to being extra environmentally pleasant.