A new method to print microchip designs on curvy surfaces has been discovered by a researcher

Gary Zabow, a NIST scientist, had never planned to use candy in the lab. It was only as a last resort that he had even tried burying microscopic magnetic dots in hardened chunks of sugar—hard candy, basically—and sending these sweet packages to colleagues in a biomedical lab. The sugar dissolves in water and the magnetic dots are free to study without any chemicals or harmful plastics.

By chance, Zabow had left one of these sugar pieces, embedded with arrays of micromagnetic dots, in a beaker, and it did what sugar does with time and heat—it melted, coating the bottom of the beaker in a gooey mess.

He thought, “No problem.” He would dissolve the sugar as usual. The microdots disappeared when he washed the beaker. They weren’t actually missing. Instead of being released into the water, the microdots had been transferred to the bottom of the glass and were creating a rainbow reflection.

Zabow recalls that it was the rainbow colors that truly surprised him. The colors suggested that the microdot arrays had kept their distinctive pattern.

He was inspired by this sweet mess. Could regular table sugar be used in place of microchips to create new surfaces with the same power? The findings of Zabow on the potential transfer printing process were published by Science November 25, 2005

Microprinting is a process that places precise patterns on surfaces to give them new characteristics. This includes semiconductor chips, micropatterned surfaces and electronics. These tiny mazes of metals, and other materials were traditionally printed on silicon wafers. As the possibilities for smart materials and semiconductor chips expand, intricate patterns of metals and other materials will need to printed on unconventional, non-flat surfaces.

These patterns are difficult to print directly on these surfaces so scientists transfer them. Although flexible tapes or plastics can be used (such as to pick up newsprint), these solids can have problems conforming to corners or sharp curves once the print has been laid back. They can also leave behind chemicals and plastics that can be difficult to remove, or dangerous for biomedical use.

Liquid techniques use transfer material that is placed on top of water, and then the target surface is driven through it. It can be difficult to place the print on a new surface if it flows freely.

Zabow was surprised to discover that a simple mixture of caramelized sugars and corn syrup could work.

The sugar mixture can then be used to cover micropatterns with a small amount water. The candy hardens once the water has evaporated and the pattern can be pulled out. The candy with the printed pattern is placed on top of the new surface, and then melted. As it melts, the sugar/corn syrup mixture retains its high viscosity. This allows the pattern to maintain its arrangement while it flows around curves and edges. You can wash the sugar with water and leave the pattern.

This technique is known as REFLEX (REflow–driven FLExibleXfer), and microcircuit designs can be transferred to form a stencil for scientists or manufacturers to etch the correct materials. Alternately, the patterned materials can be transferred from the original chip onto microbeads or fibers to allow for biomedical and microrobotics research, or on sharp or curved surfaces in new devices.

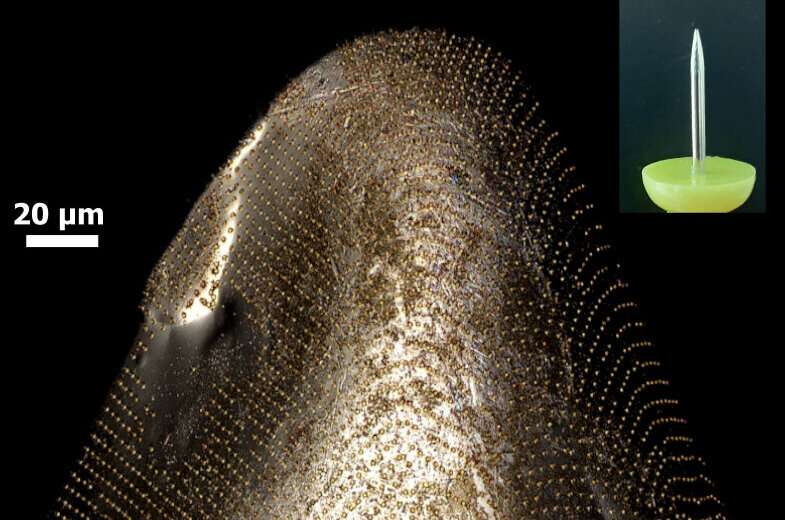

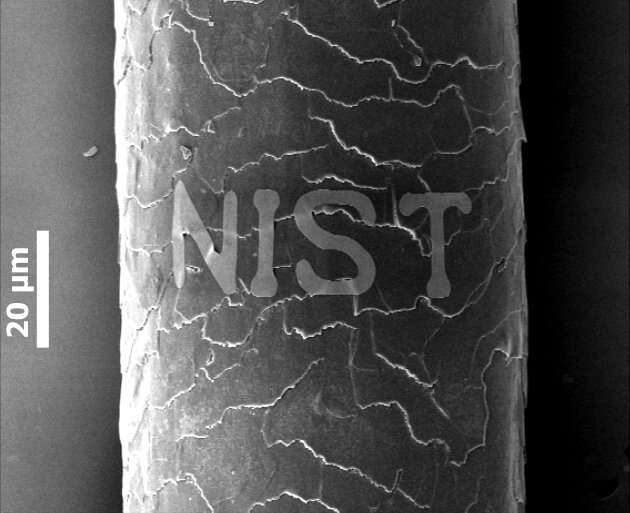

This technique was successful on a wide range of surfaces. It included printing onto the point of a pin and writing “NIST” in microscaled gold lettering onto one strand of human hair. In another example, 1-micrometer-diameter magnetic disks were successfully transferred onto a floss fiber of a milkweed seed. The magnetically printed fiber reacts to the magnet and shows that the transfer was successful.

REFLEX has much more to offer, but it could lead to new materials and microstructures in a variety of fields including electronics, optics, biomedical engineering, and others.

Zabow says that the semiconductor industry spent billions of dollars to perfect its printing techniques in order to produce chips we depend on. “Wouldn’t that be wonderful if we could leverage some technologies, increasing the reach and affordability of those prints with something as simple as a piece or candy?

G. Zabow, Reflow Transfer for Conformal Three-dimensional Microprinting Science (2022). DOI: 10.1126/science.add7023. www.science.org/doi/10.1126/science.add7023

National Institute of Standards and Technology

Citation:

A researcher discovers a new way to print microchip designs on curvy surfaces (2022 November 24, Researcher)

Retrieved 27 November 2022

from https://techxplore.com/news/2022-11-sweet-microchip-patterns-curvy-surfaces.html

Copyright is reserved for this document. This document is not intended to be used for research or private study.

Part may not be reproduced without written permission. The information is provided only for informational purposes.