[Review] Creality CR -Laser Falcon Engraver

The Creality CR-Laser Falcon Engraver has been reviewed by the 3D Printing Industry engineering group.

Creality, a Chinese company, is involved in the manufacturing of 3D printers. They are well known for the CR & Ender range, which are very successful printers in the desktop and prosumer market due to their low price and overall quality.

Creality has not yet released a laser cutter called the CR-Laser Falcon Engraver. They have also previously released a laser accessory for the Ender 3S1 3D printer.

The company hopes to be a success in the laser cutter market. It is targeting individual makers and not industrial clients. The machine is manufactured in China along with Creality’s other machines and is made to the same standard. It ships to Europe from China and is well-packed with foam insulation made-to-fit.

The Laser Falcon was introduced early in the year and received positive reviews. There are two product variations, a 10W version & a 5W version. Current prices are $493 (10W) and $322 (5W). The 10W model was the one we reviewed.

For anyone who is looking to express their creativity in a new way, the Falcon is an excellent choice. Combining 3D printing and laser cutting can produce new products. The machine’s price is significantly less than those on the market with similar workspace and power. It’s very simple to use, provided you keep your machine safe.

Creality Creality CR–Laser Falcon 10W. Dymaxion Plywood Globe. Photo by 3D Printing Industry.

If the machine is misused, it could prove to be dangerous. For example, when engraving stainless steel or shiny materials, the laser could reflect off the surface and enter your eyes.

The standard and product do not include an air compressor. This is because the air-assisted nozzle reduces cutting quality and increases smoke emissions from wood. These extras can be purchased for the laser and will greatly improve the user experience. These items currently cost extra and are available on Creality’s website.

Although our initial thoughts were positive, we were still apprehensive as to how the machine would compare to other laser systems. We tested power, speed, and passes to determine the best combination to cut/engrave the material. Lightburn software was used because it was the best choice that Creality recommended. Multiple materials were used in order to determine the effectiveness of the laser under different circumstances.

In this article, we will discuss the above points and briefly describe the features of CR-Laser Falcon.

Creality Creality CR Laser Falcon 10W. Air-assisted lens & Compressor. Photo by 3D Printing Industry.

Creality CR-Laser Falcon Engraver

Two ways to control the CR-Laser Falcon are available. One is by pressing a button on the machine. The other is connecting a computer and running Lightburn laser software. You can manually level using a leveling tool in tandem with the two bolts on the side.

This is a simple, but very effective way to offset the laser at the right distance from the material.

The laser frame itself is made of aluminum extrusion. The assembly is done using long M3 bolts. This makes the structure very stable when it is in use, and it does not become affected by the inertia generated by the laser module.

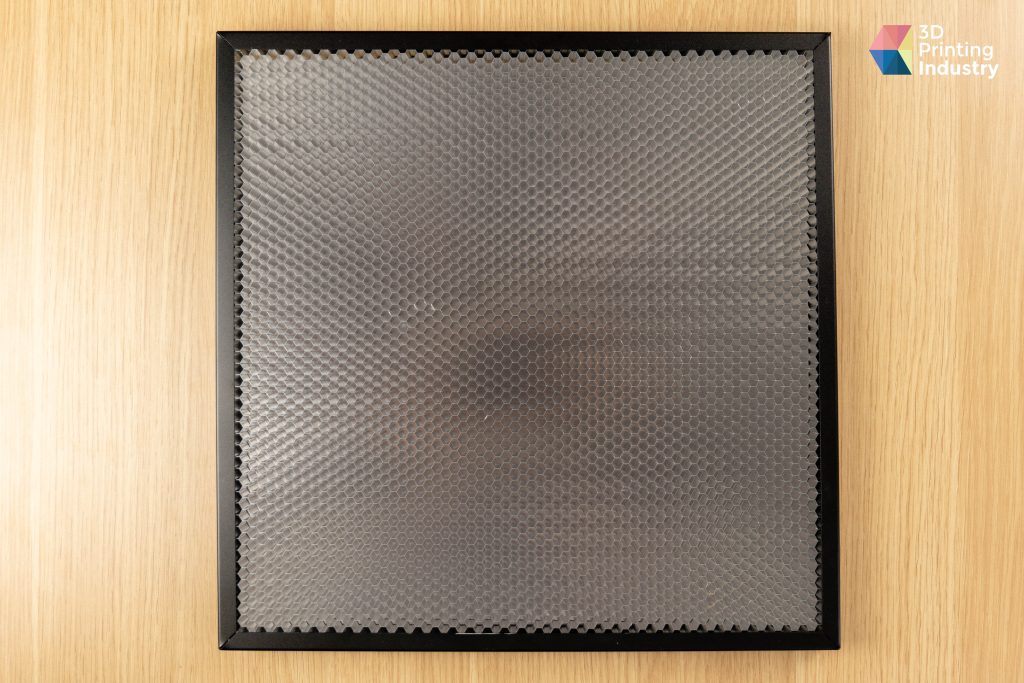

Maximum build space is 400mmx415mm. This is slightly larger than an A3 piece of paper. You will have to buy an additional cellular board measuring 320 x 325mm. This is insufficient for pieces that require a large workspace.

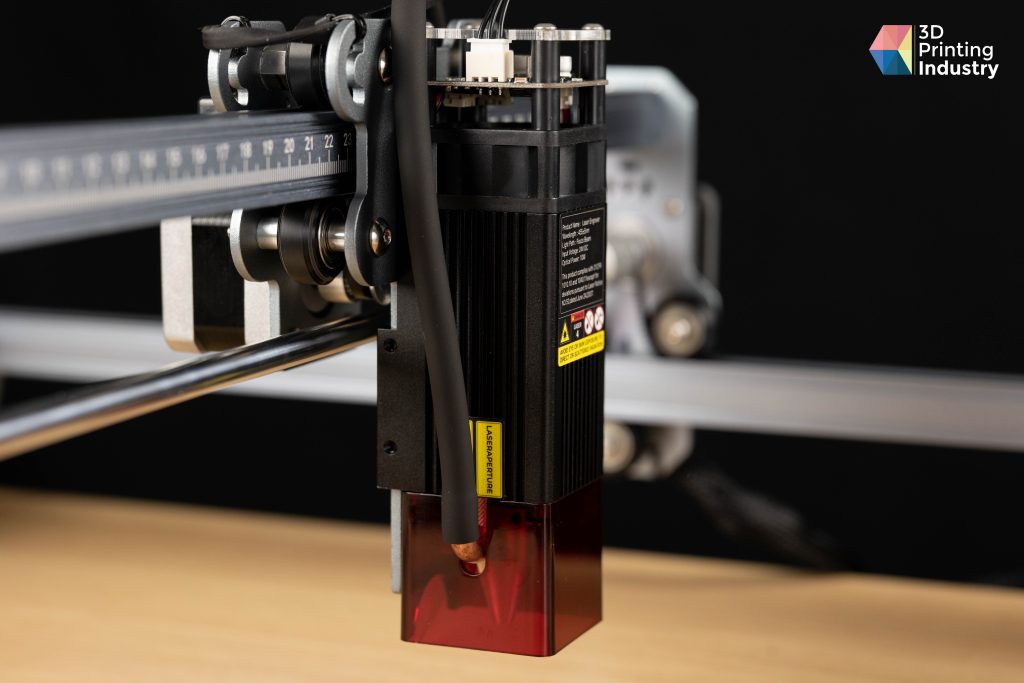

The laser module itself contains a single Class 2 10W laser with a wavelength of 455±5nm. It has a resolution of 254 dpi, and a compressed engraving spot of 0.06mm. The laser can cut 18mm of softwood and can engrave up to 10mm in depth depending on the material. Among other materials we tested, the laser cut stainless steel and polypropylene as well as rubber, rubber ceramic, bamboo, and plywood.

Creality Creality Creality Laser Falcon 10W. Examples of engraving projects Photo by 3D Printing Industry.

This machine’s advantage is its ease of use, which is a major selling point. It offers a lot of creative possibilities and has no barriers to entry like other manufacturing areas. Creality offers DIY builders and DIYers new possibilities. Previously, to use the machine you needed an industrial machine with a large ventilation system.

The Laser Falcon is priced well considering the high quality of the product.

First Impressions and opening the Creality CR-Laser False Engraver

The Laser Falcon was shipped in foam, which protects it against external damage. Because the laser module is the most sensitive component of the machine, it was protected very well. Other contents included the bolts for assembling the falcon, the legs and the chassis.

You received additional boxes with the package. They were well-protected and came in separate boxes. These were the extended legs of the printer, the compressor, and the lens fix. The Laser Falcon was easy to assemble. It took approximately 5 minutes to unbox and then to use the laser. This does not include time to download design software or make any other preparations.

Creality Creality Creality Laser Falcon 10W. Unboxing separate parts Photo by 3D Printing Industry.

Software options available on the CR-Laser Falcon Engraver

The laser has limited software options. There are two main programs, these are laserGRBL & Lightburn. Creality has neither software nor ownership rights to these programs. These third-party programs can be quite different. LaserGRBL is an older program and has a limited number of options and parameters. This software was used during testing, but we quickly switched to Lightburn because it is more advanced. The Laser Falcon’s profile can be downloaded onto these programs for an accurate workspace.

Lightburn was chosen because it can be used to alter the speed, passes, power, and speed of the design. This is done by allocating a certain color to a line or shape. It is intuitive and simple to use even for someone with no previous laser cutter experience. Lightburn also offers a derivative tool within the program, which allows users to scale and create designs with compound shapes and line tools.

Frame the design onto the material. This is when the laser can be turned on at low power. It is used to show the area it will cut/engrave. This is extremely useful for cutting precise designs.

Laser Benchmark Testing the CR-Laser Falcon Engraver

Before we cut or engraved any of the detailed pieces, we first ran some tests to gauge the Falcon’s ability. These tests consisted of basic testing using standard cutting and engraving parameters.

The first thing we tested was the engraving’s level of detail. We used a simple monogram consisting of descending circle sizes. The cutter did a fantastic job and was able to create a very high resolution engrave.

Our next test was more interesting. 3DPI logos could be cut and engraved onto plywood. This was chosen as the medium for laser cutting projects because it is widely used. These results were fascinating and showed a spectrum of speed vs. strength. The perfect combination of speed and power to achieve a clean, precise cut in just one pass was found at 3 mm/s speed with 100% power.

Creality CR–Laser Falcon 10W. Laser & Engraving capability test. Photo by 3D Printing Industry.

Also, the engraving was done at different distances to the wood. This was done in order to verify the focus of the leveling device.

Engraving and cutting were done using the air-assisted instead of the regular nozzle. Air assist was used to cut at the optimal distance of 3mm. This allowed for flames and burn marks to be avoided. For engraving, the ideal distance is also 3mm. To get the best result, air should be disconnected or the standard lens installed.

Compared to Creality’s parameter sheet, these results match up. As your materials and machine may behave differently to what we have sourced, it is worth testing them yourself.

We have also tried the laser cutter with different materials. These experiments produced very good results.

Framing using different methods

Software is more convenient than using the button on the machine. Software has framing functions which can help you position your workpiece. Lightburn allows you to do this in two ways. Either frame the design in a square or create an abstract shape that follows the outer edges of the piece. This can be adjusted depending on the size and visual feedback of your piece. The power options for this mode should not exceed 1-3%. This will allow for better visibility and prevent prematurely burning of your material.

LaserGRBL has a framing function, but it is more abstract than Lightburn. The UI should be improved and the visual display for the laser-cut file should be more attractive and clear. Lightburn offers more control than the button on the button. It is simple to use. You can pause or restart the cut using different settings in the software. The button will allow you to edit the file and reload your SD cards. These are only a few of the applications that you can use.

Lightburn is our recommendation because it offers all the features and options that you need to use the laser cutter.

Creality Creality CR–Laser Falcon 10W. Here are some methods of sending files to your machine. Photo by 3D Printing Industry.

How can I improve the CR–Laser Falcon Engraver

This machine, like all machines of its kind that ship without a protective cover is susceptible to fumes because it does not have any ventilation equipment. This is a problem when cutting materials like MDF that can cause cancer. It is important to have an effective system in place for any type of cutting. Creality informed us that a protective layer to remove soot from the cutting surface will be made in 2023.

Another minor, but potentially frustrating problem with this product is the extra cellular board. This is another issue that has been seen in similar systems. It is smaller than an A3 sheet of paper and is not large enough to cover the work area. It could be interpreted that the product was designed to reduce costs and accommodate users who might already have the honeycomb boards in their workshops. Creality states that the majority of users require a work area of 300×300. By meeting these requirements, product and shipping costs can be reduced.

Final verdict on CR-Laser Falcon Engraver

The Falcon is a very efficient machine, and build quality is a high standard equal to Creality’s other machines currently on sale. It is affordable and will appeal to desktop users and small workshop owners.

The Falcon was very precise when engraving hard materials. We produced many fine designs using ceramic and stainless-steel. We found that engraving plywood is easier without an air-assisted nozzle. This could be due to the fact that the setup delivers more oxygen, which results in a rougher and faster burn.

It is easy to level. This machine has an advantage over laser cutters that we used in the past. They require a more complicated method of leveling the head. This step is crucial as it will affect the quality of your results if the laser is not properly offset.

Because of its size, this laser cutter is unique among others. Many desktop DIY laser cutters are small in build volume and have compact structures. Creality Falcon’s build volume is comparable to an industrial cutter. High-end cutters have more safety features, such as fume extraction and protective casings. This raises the cost of the units. To achieve a lower price for consumers, Creality has removed some safety features.

When used responsibly with the right safety measures in place, this laser cutter isn’t unsafe, but a certain level of maturity is required.

This laser cutter exceeded our expectations and we are extremely pleased with the results. The laser cutter/engraver is very precise when cutting plywood and has excellent resolution for engraving hard materials. The laser guard prevents most of the laser beams from leaving the work area. It is important to exercise caution when engraving textural materials, as they are more susceptible to being reflected back past the guard.

We are extremely happy with the product overall and would recommend it to hobbyists or designers who want to make detailed custom products for a low price.

Creality Creality CR Laser Falcon 10W. Engraving & Cutting Projects. Photo by 3D Printing Industry.

The CR-Laser Falcon Engraver is available direct from the company here, use the code “Falcon3dp” to get $30 off.

Creality offers several Black Friday discounts to customers exclusively. Up to 30 November Code-FA80 will be $363.70. This is a $80 discount

The CR-Laser Falcon Engraver is also available direct from Creality, use the code “Falcon3dp” to get $30 off. Valid Until 30th November.

Featured image: Creality CR-Laser Falcon 10W. Photo by 3D Printing Industry.